Services

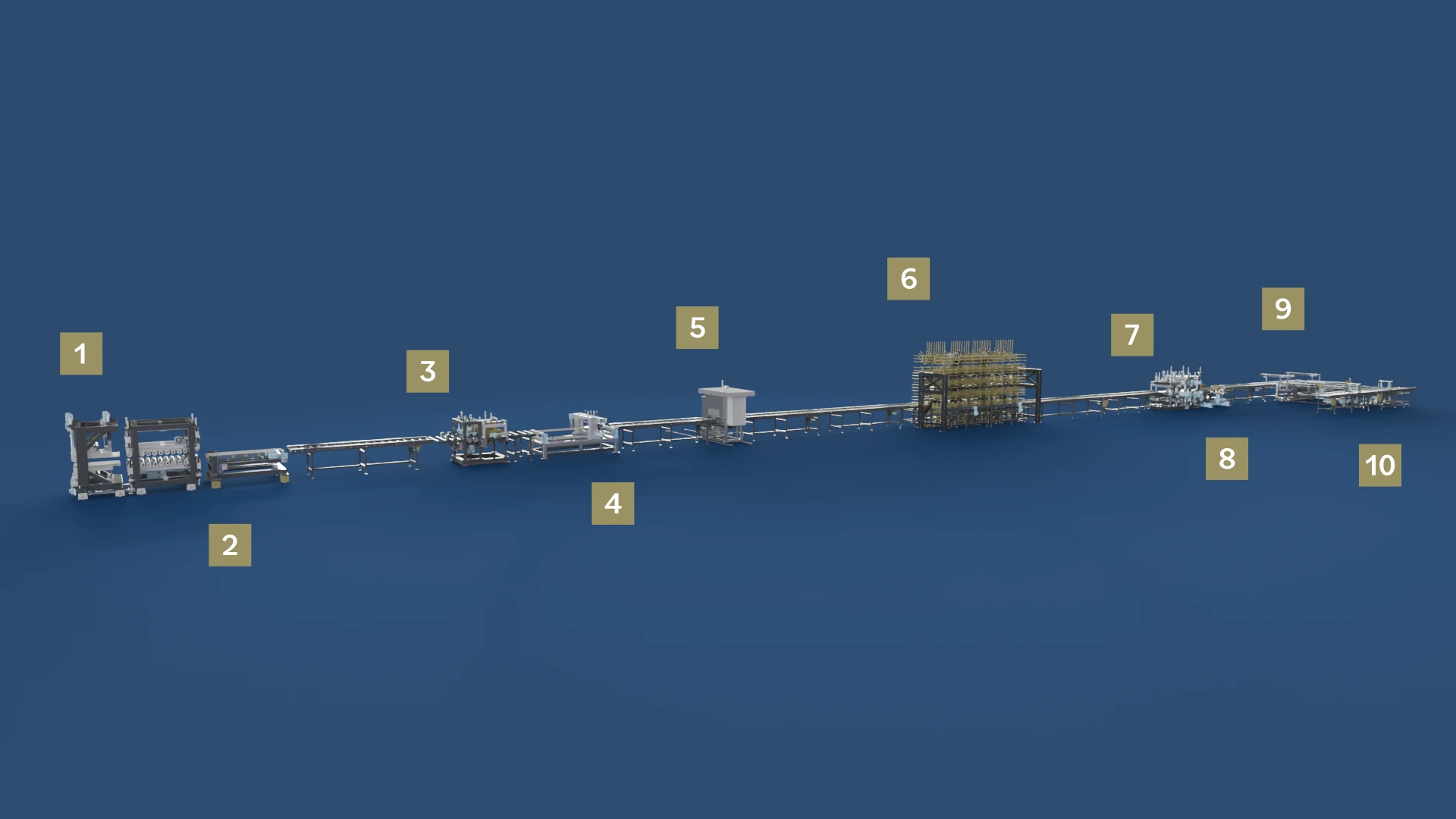

Downstream lines for insulation and foam

With 30 years of experience, we design and build production equipment for the insulation industry – not just machines, but solutions that give our customers a true competitive edge. Our modular systems can operate as stand-alone units, bypass modules, or integrate seamlessly into existing production lines, ensuring maximum flexibility.

Standard Solutions

Production equipment for insulation and foam boards

Special solutions

Customized Equipment for Your Production

Standard equipment not quite right for your production? Our team works with you to create tailor-made solutions, perfectly aligned with your manufacturing needs.

Equipment Upgrades and Rebuilds

Retrofits

Outdated production equipment? Our retrofit solutions and upgrades for IWI and third-party components modernize your insulation plants, saving energy, enhancing productivity, and maximizing efficiency.

Benefits

Our solutions for your success

Standard and special solutions

30 years of expertise in insulation and foam processing

Modular design: flexible integration into existing production lines

Retrofit & Upgrades: for IWI and third-party components

Service & Support: repairs, technical assistance, and remote maintenance

Continuous optimization: enhancing performance of our systems and machines

Machine Capabilities

Maximum Material Utilization

Capacities: 250 - 3.000 kg/h

Thickness: bis 400 mm

Width: bis 1.600 mm

Length: bis 8.000 mm

Our Services

From Design to Commissioning

Planning and Design

Every custom plant begins with a thorough consultation. Our expert team works with you to create the optimal concept, followed by engineering and design with cutting-edge CAD software to guarantee maximum precision and efficiency.

Commissioning

We ensure your new IWI production equipment runs smoothly from day one. Our team delivers comprehensive, hands-on training on-site, equipping your staff with the skills and know-how they need.

Production

Our core plant components are designed, fabricated, and tested in Germany – from planning and assembly to wiring and programming. All parts are heat-dried, powder-coated, and, if needed, galvanized for maximum durability.

Support

Our support team is ready to assist you, keeping your production running smoothly.

Your contact

Get

in Touch

now

in Touch

now